There are numerous ways to bond metal to metal, so why choose an adhesive method? Here we look at some of the different ways, such as fastening and welding and why a metal adhesive offers a superior outcome.

Fastening – Screwing and bolting are common methods for attaching metal surfaces to each other. They are often used for temporary or semi-temporary joints. However, such fastenings are prone to several problems, including corrosion, loosening and the need for accurately placed holes to fasten to. A metal adhesive, however, is just as suitable for temporary joins and when removed, will leave no damage or evidence behind like bolts and screws do. Adhesives are lighter, seal against corrosion and offer a more even distribution of weight over the surface making the structure stronger. Some adhesives also offer heat and chemical resistance. For Metal bonding adhesive, visit a site like Metal bonding adhesive from CT1

Welding – Similar to adhesives, welding offers better stress distribution. Welding also doesn’t require the holes that screws and bolts do. However, welding is a specialist task that requires certain labour and training costs whereas adhesives don’t. Welding also requires inspection afterwards but adhesives don’t. Only a basic level of training is required to use metal adhesives, making it a more cost effective option. Welding involves rapid heat fluctuations that can damage the metal and make it more prone to corrosion.

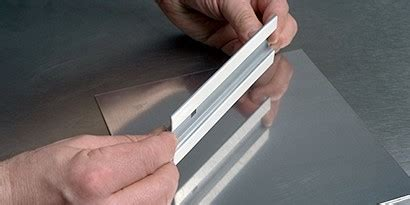

Metal adhesives often don’t require high heat application and leave no damage to the surface of the metal. This is what makes them such a popular choice.