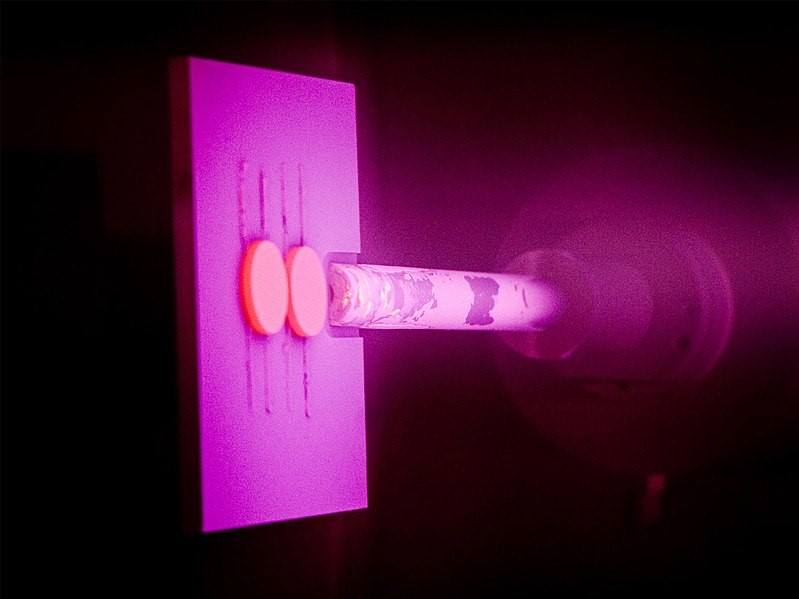

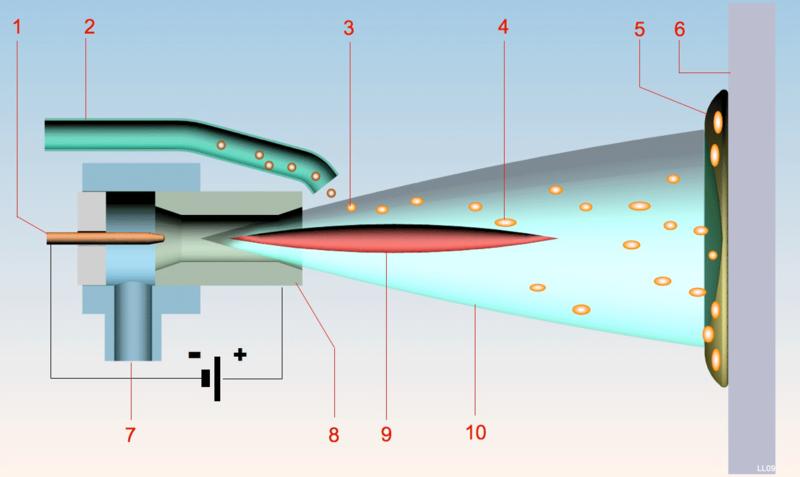

Thermal spray coating is a spray coating method and engineering practice that applies droplets to coat materials. These materials can vary in thickness and in size. Thermal spray coating as an engineering method has been an established process for many years. It is widely available in a variety of sectors.

The Process of Thermal Spray Coating

Thermal spray coating and thermal plasma spray involve putting materials on metal, ceramics or polymers. Materials are melted or turn into plastic in the process.

Advantages and Disadvantages of Thermal Spray Coating

Thermal spray coating has a range of advantages and disadvantages. According to Bodycote, these include corrosion protection, wear resistance, clearance control, heat and oxidation resistance, temperature management and electrical conductivity. Advantages also include a variety of different coating and substrate materials and extended longevity of the substrate material, as well as cost-efficiency. Disadvantages include the invisibility of the substrate and the inability to evaluate effectiveness. Another key disadvantage is that the thermal spray coating method is expensive to set up.

Wide Range of Coating and Substrate Materials

There is a high versatility in both substrate and coating materials, which means that many different materials can be transformed into coatings using the thermal spray method. These materials include metal, alloy, ceramic plastic and polymer. The number of substrate materials is large, and as long as the material can endure the heat the material can be successfully coated.

Extended Substrate Longevity and Cost-Efficiency

A thermal spray coating or thermal plasma spray that is strong and efficient will ensure durability. Thermal spray coating ensures that the end product is less susceptible to corrosion or general deterioration. As thermal spray coating is usually thicker than other coating methods, it guarantees better protection. Additionally, thermal spray coating is nearly always more cost-effective than buying or making a product.

Disguised Substrate and High Cost

Thermal spray coating is a highly efficient method, as the substrate material is nearly impossible to identify. In this way it can nearly always be presented as something else. This is positive if the origin material needs to be concealed, but it is a disadvantage if the substrate material needs to be recorded. Additionally, although thermal spray coating is a cost-efficient method, thermal spray coating equipment can be highly expensive.