In the thermal spraying process, there are five main types. In each of the five methods, a consumable material – such as wire or powder – is heated and directed towards the substrate. The main distinctions of the processes lie in the heat source and the speed of the particles before they contact the substrate. The choice of process significantly influences the quality of the coatings produced, with each method offering unique benefits.

Let’s delve into each of the five processes:

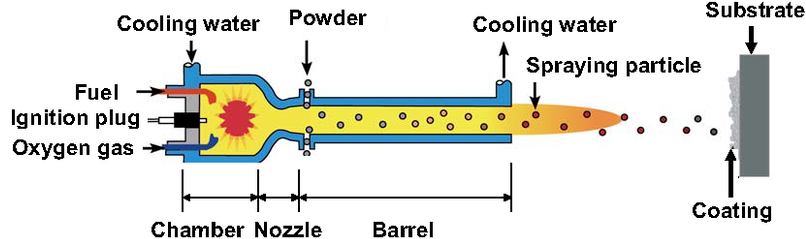

1. HVOF spraying

2. Flame spraying

Flame spraying is a method that relies on the heat produced from the combustion of a fuel (gases such as acetylene, propylene, propane, or hydrogen) and a mixture of oxygen to heat a consumable, either a wire or powder. Compressed air, inert gas or the Venturi effect propels the consumable toward the substrate.

3. Detonation gun spraying

Detonation gun spraying involves detonating a mixture of acetylene and oxygen to generate a shock wave, propelling the powder consumable toward the substrate at exceptionally high speeds. These coatings often boast exceptional quality, setting the standard for other coating processes.

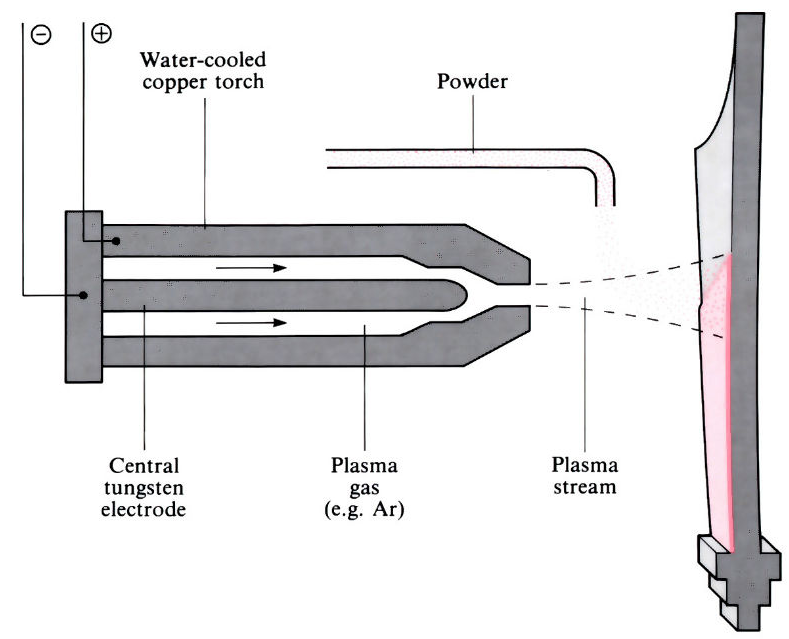

4. Plasma spraying

Plasma spraying, which incorporates thermal plasma spray technology, uses a DC electric arc to generate a high-temperature plasma gas. Inert gas fed endlessly into the torch increases rapidly when heated and ionised, resulting in a high-speed jet. Thermal plasma spray technology enhances the process by further optimising the heating and particle acceleration mechanisms, resulting in even more precise and robust coatings.

5. Arc spraying

Arc spraying is known for its high productivity. It involves creating a direct current electric arc between two consumable wire electrodes, which melt to form the spray material. Compressed gas then atomises the wires and propels the droplets toward the substrate.